Across the nation and around the globe, College of Engineering alumni, industry partners and faculty are using their unique skills and resources to combat the COVID-19 coronavirus. From stabilizing the Cloud and on-line conferencing platforms, to pivoting production of manufacturing to produce PPEs, to researching the detection, transmission and prevention of the virus, the college community has mounted an extraordinary counteroffensive. We are proud of each and every one of you, and invite you to share your story with us.

Here are just a few of the many examples of College of Engineering people doing extraordinary things. To be included on the COE “honor roll” of corona virus responders, please send a short message to Marilyn Davies at mdavies@coe.utah.edu

ALUMNI AND INDUSTRY RESPONSE

Mark Fuller: WET

Mark Fuller, (HCV ’76) who is the CEO and Chairman of WET Enterprises, Inc. in Sun Valley CA, was praised recently by the Mayor of Los Angeles Eric Garcetti, for his rapid response to the corona virus pandemic. Mark converted part of his design and manufacturing facilities for high-end fountains to producing face shields for the doctors and health providers in the Greater LA area. He is a member of the College of Engineering National Advisory Council.

Paul Mayfield: Microsoft

Paul Mayfield, (BCS ’97) Director of Program Management Enterprise & Mobile Client at Microsoft, reports that his team’s technology is part of most large organization’s work-from-home infrastructure. As the usage of Microsoft systems continue to rise by an order of magnitude, the company is working around the clock to assure uninterrupted service to its clients. Paul is a member of the College of Engineering National Advisory Council.

Chris Durham: Merit Medical

Chris Durham, (MEN ’98, BEE 1991) Executive Vice President for Acquisition and Product Integration at Merit Medical Systems, Inc., reports that Merit is involved in the fight against COVID-19 at various sites across the globe. The company is working overtime to provide products for the ICU, including pressure infusion bags, fluid administration sets, and CVC catheters. In Utah, Merit is working with the state in an effort to provide needed supplies for COVID testing. Chris is a member of the College of Engineering National Advisory Council.

Ken Muir: Micro Focus

Ken Muir (BCE, BEE ’95), is the General Manager and Vice President of Analytics/IDOL, Ops, Security & Strategy for Micro Focus, a company that serves massive financial and other large business with strict compliance issues. Micro Focus has had to scale up its operations and move some of these customers from capturing communications of just a few thousand users to 120,000 users overnight. While stressing it teams, its SaaS offering is holding up well. Ken is a member of the College of Engineering National Advisory Council.

John LaLonde: Bright Path Labs

John LaLonde (BCS ’89) is co-founder of Abstrax, Inc. and current chair of the College of Engineering’s National Advisory Council. He also serves on the board of Bright Path Labs, a biotech company on the front lines of the pandemic. Because roughly 80% of the basic components used in US drugs, known as active pharmaceutical ingredients come from India and China, the current crisis has exposed gaps in America’s drug supply. Bright Path’s game-changing technology is positioned to immediately fill gaps in the drug supply chain in response to the COVID-19 pandemic; including the agile manufacturing of hydroxychloroquine (HCQ), and other potential treatments or subsequently discovered vaccines and medicines to address future health challenges.

Bert Bunnell: Bunnell Incorporated

Bert Bunnell (BS BCH ’69) is the retired chairman and CEO of Bunnell Incorporated, the company he established in 1980, to provide advanced ventilation systems for treating premature infants in acute respiratory failure, an often fatal complication of preterm birth. The company manufactures, markets, and services its products for hospitals across the globe. Since its introduction, the Life Pulse® Ventilator has helped health care professionals save approximately 200,000 infants. The company is committed to maintaining its production through the pandemic to provide support for our most vulnerable patients.

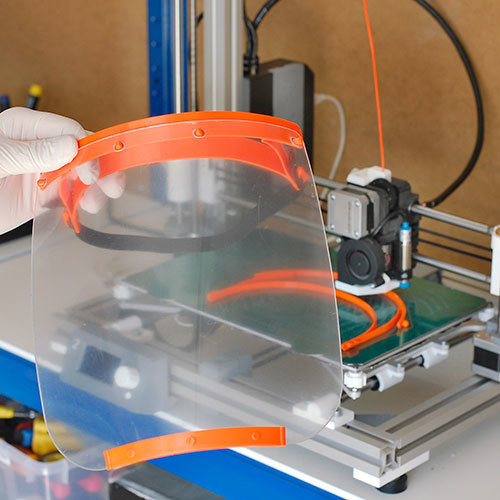

Meldrum Innovation Lab

University of Utah engineers are using the university’s 3D printers, laser cutters and other equipment to create new personal protective equipment (PPE) in an effort to keep up with the needs of health care workers who are treating COVID-19 patients. Part of this campus-wide effort involves creating face shields for medical workers by printing individual components and then assembling the masks into a final product. Other U offices that are part of this initiative include the J. Willard Marriott Library, Spencer S. Eccles Health Sciences Library, the Center for Medical Innovation, and Lassonde Entrepreneur Institute, all of which have 3D printers. All efforts towards 3D printing from the College of Engineering have been consolidated in the Meldrum Innovation Laboratory to reduce the risk of contamination.

Kurt Kottke: Autoliv

Kurt Kottke (BME ’86), is a Senior Director of Engineering at Autoliv, and a member of the College of Engineering Industry Advisory Board. Kurt reports that Autoliv has teamed up with Coleman Knitting Mills in Ogden to produce garments and masks for the medical industry. Autoliv’s Tech Center took over the cutting responsibility for masks and garments using a laser cutter. This freed up their sewing associates to focus on sewing and assembly. Every day, Coleman provides mask or garment rolls and within hours, Autoliv sends back several hundred cut pieces for their team to sew and assemble and distribute to local and state medical caregivers.

Kristiane Koontz: Zions Bank

Kristiane Koontz is Executive Vice President and Banking Transformation Director at Zions Bancorporation and a member of the College of Engineering’s Industry Advisory Board. She reports that Zions’ coronavirus task force meets regularly to respond to evolving conditions, monitoring local health department and CDC updates, and executing the company’s pandemic plan. Bankers are reaching out to assess client needs, exploring payment deferrals and loan extensions, when conditions permit. Additionally, Zions has generally placed a moratorium on foreclosures. Thousands of employees across the company are working to streamline the operations and approvals of SBA Paycheck Protection Program loans for small business clients.

Ryan Packer: Adobe

Ryan Packer is vice president of engineering for Adobe in Lehi and a member of the College of Engineering Industry Advisory Board. He reports that Adobe has developed a comprehensive response to the pandemic throughout the company’s products and services. With many schools and universities worldwide closing their campuses for on-site classes, Adobe is providing schools and universities that have had Creative Cloud access in on-site computer labs with temporary at-home licenses of Creative Cloud desktop apps for their students and faculty, at no additional cost. Access is being granted through May 31, 2020, though that date could be extended to enable students to continue their learning remotely.

Tyler Reid: GoEngineer

Tyler Reid (BME ’09) is the Manufacturing Application Director for GoEngineer in Salt Lake City. His company sells industrial 3D printers across the United States. The company and many of its customers have put them into full-time production of various PPE. They are focusing on additively manufacturing face shield visors with a throughput of about 150/day. The visors are being sent to Stratasys for assembly and further distribution as part of their nationwide COVID-19 response initiative. Some customers have shifted their production to other types of PPE such as facemasks, ventilator splitters, test swabs, and more. Healthcare facilities are requesting specific design changes and GoEngineer is building unique designs for specific customers, on-demand. While 3D printing is not a long-term solution, it has filled the gap and helped prove out designs for mass production.

Phil Triolo: Phil Triolo and Associates LC

Phil Triolo (PhD ’88) is a regulatory affairs professional specializing in FDA and EU medical device regulations, with an adjunct position in the Department of Biomedical Engineering where he lectures on FDA requirements for medical devices. He is providing pro bono services to MIT to assist them in obtaining Emergency Use Authorization for a simple ventilatory assist device designed by MIT undergraduates. The device automates the compression and relaxation of commonly available resuscitation bags. Phil’s role is to identify regulatory requirements, interface with the FDA, and document the safety and effectiveness of the device to address regulatory requirements.

JoAnn Lighty: Boise State University

JoAnn Lighty (PhD ’88) is the dean of engineering at Boise State University. She has been actively engaging BSU’s Engineering Innovation Studio in the 3D printing of face shields along with the library maker lab and makers across the state. So far, they have produced more than 570 face shields with headbands that were printed by the community. They have also engaged corporate makers, specifically the Micron 3D printing club.

Brian Verwer: Micron

Brian Verwer is the senior manager for academic and community relations at Micron in Lehi, Utah and a member of the College of Engineering’s Industry Advisory Board. Brian reports that, overall, Micron has dedicated $35M to support the global relief effort, including $250,000 to Utah’s first responders, testing and the Utah Food Bank. Additionally, Micron team members came together with their own 3D printers and to print about 2,000 face shields/week for Silicon Slopes.

Robert Galloway: US Synthetic Corporation

Rob Galloway (BME ’97) is president of US Synthetic Corporation and a member of the College of Engineering Industry Advisory Board. His company is using their bank of 3D printers to make masks for law enforcement and fire fighters. Their process cuts N-95 masks into four sections and inserts them into the masks to make them last longer. US Synthetic engineers and their kids have also printed masks at home to support the effort.

Eric Jensen: Causality Link

Eric Jensen (BCS, MS ’06) is the CTO and co-founder of Causality Link, a Utah company built on natural language processing and artificial intelligence. The company’s primary business is focused on helping analysts and investors. When the pandemic began having such a dramatic effect on the economy and everyday lives, they decided to create and publish analytics available to the public for free, based on translating and reading tens of thousands of news sources across the globe every day. They update their charts every hour and plan to be adding a number of new features and analysis. Causality Link’s dashboards around Coronavirus can be viewed here

Center for Medical Innovation

Annie Fonnesbeck (BS, MS, BIOE ‘17) is the Engineering Laboratory Manager for the University of Utah’s Center for Medical Innovation. She, along with research associate professor Tomasz Petelenz and chemical engineering student Jared smith, has been part of the team involved in designing a new version of a powered air-purifying respirator system. The PAPR system is a reusable PPE device that health care workers can use when working with COVID-19 patients. Like older PAPR models, it has two main components. First, the operator will strap a portable fan system around the worker’s waist like a belt. It blows purified air through a tube to a hood and helmet that the health care worker will wear. The new system will help to protect the health care worker from exposure from the coronavirus.

Lorenzo Swank: Ignite Innovators

Lorenzo Swank, (BCE, MS, ’11) Venture Partner and Entrepreneur in Residence at Ignite Innovators, reports that Ignite Innovators is working directly with groups such as the Michigan Health and Hospitals Association to source COVID-19 testing kits from South Korea. Ignite is working to connect local and state health departments, hospitals, and medical professionals in the United States with their counterparts in South Korea.

Del Wilson: Powered Air Purifying Face Shield

Del Wilson completed a BS (’78) and MS (’81) in mechanical engineering, and spent his career with the Boeing Company from 1978-2019. At the start of the pandemic, he began printing 3D face masks while researching how the coronavirus spreads. Ultimately he concluded that face masks, while helping considerably, do not provide complete protection. He recently developed a Powered Air Purifying Face Shield and is pursuing further research in the hopes of commercializing his concept.

J. RYAN STANFIELD: MOOG

Ryan Stanfield, (BS, MS, PhD 2012 Mechanical Engineering) is the Director of Engineering at Moog Medical and adjunct faculty with the University of Utah’s Department of Mechanical Engineering. Moog’s group in SLC makes infusion pumps. All patients on a ventilator (including COVID-19 patients) require one or more infusion pumps – for the infusion of IV drugs or food. Moog employs many graduates of the University of Utah’s College of Engineering. Other Moog facilities also produce blower motors and pumps (for ventilators, oxygen concentrators, etc.), and PPE in response to, and prior to, the current pandemic.

Faculty Research

The Office of the Vice President for Research in partnership with the Immunology, Inflammation and Infectious Disease (3i) Initiative at the University of Utah has awarded $1.3 million in seed grants to more than 55 cross-campus projects that will examine a host of issues arising out of the COVID-19 pandemic. The projects fell into six broad categories:

College of Engineering faculty submitted 17 proposals and so far received funding for ten. The funded projects include:

Assistant Professor Krista Carlson: Materials Science and Engineering

Synthesis of Easily Sterilizable and Reusable Xerogel Filters for N95 Respirators: Manufacturers of single-use N95 respirators cannot keep up with the current global demand due to manufacturing limitations. We propose to make a silica xerogel filter that provides N95 filter efficiency, but unlike the single-use respirators or current filters for reusable respirators, our xerogel filters can be repeatedly sterilized for reuse. Filters will be made by drying silica-based gels to obtain crack-free xerogel filters that fit into reusable respirators. Particle filtration will be tested using a U.S. Food & Drug Administration approved protocol. Data collected from this study will be used in future proposals to study filtration efficacy with viruses.

Assistant Professor Jiyoung Chang: Mechanical Engineering

COVID: Understanding the capturing and evolution behavior of wetting and non-wetting aerosols on nanofibers matrix: Recent studies show that the COVID-19 virus can easily exist as an aerosol and be detected as a viable form over three hours, which greatly increases the levels of transmissions. The most effective way, at least for now, to prevent the contraction of coronavirus in aerosol is wearing face masks. The nanoscale fiber membrane could provide an effective and affordable solution for the filtration of virus aerosol. This proposal aims to investigate the nanoscale capture and evolution of aerosols on polyimide nanofibers which can serve as an important foundation for the development of advanced filters and masks.

Professor Ramesh Goel and Associate Professor Jennifer Weidhaas: Department of Civil and Environmental Engineering

Municipal wastewater monitoring based surveillance and prediction tools for community level occurrence and spread of COVID-19: Recent reports show that COVID-19 is detectable in the feces of infected individuals. While diagnostic testing of individuals and patients exhibiting symptoms is valuable, only a limited number of tests can be conducted. Sampling wastewater for COVID-19 would allow for widespread identification in trends in COVID-19 infections, provide information on the severity of the disease to aid in public health interventions and track the effectiveness of the wind-down period of the outbreak. This monitoring could also indicate asymptomatic individuals who would still shed COVID-19 in feces. Finally, should reemergence of the disease occur, sewage monitoring could provide an early warning.

Professor Andy Hong: Civil and Environmental Engineering

Disinfecting nanobubble shield against COVID-19 in hospital ER/ICU environments: Front-line healthcare workers are severely stressed by shortages of personal protection equipment that necessitate their prolonged use of facemasks, gloves, and gowns, leading to increased exposure to the airborne coronaviruses and transmission risks from patients to patients. This project will increase protection of front-line healthcare workers and patients by providing a disinfection defense against viral transmission through the air and water.

Associate Professor Hanseup Kim: Electrical and Computer Engineering

Enabling the in-situ real-time detection of COVID-19 viruses via a quantum tunneling-based nanogap sensor: Numerous on-going viral infections and their transmission pathways of the emerging COVID-19 remain still undetected. On-spot and real-time detection of COVID viruses, as they are being carried in droplets in air, would be a game changer to minimize the time delay between the outbreak and confirmed diagnosis, and ultimately contain and control disease spreads. Unlike conventional methods that mainly rely on laboratory testing that is only post-symptom or –infection diagnosis, this proposed research aims to enable the on-spot, real-time detection of COVID-19 viruses in the field that requires sensitivity enhancement by >1000 times compared to the most recent sensor technology, via utilizing quantum tunneling phenomena.

Assistant professor Jessica Kramer: Bioengineering

Understanding how different compositions of the proteins that make up mucus spread coronaviruses could help identify those who are “super-spreaders” as well as those who could be more vulnerable to becoming infected: Assistant professor of bioengineering, Jessica Kramer (BSC ’04) has received a one-year, $200,000 Rapid Response Research (RAPID) grant from the National Science Foundation to study how different compositions of mucus, the slimy substance on human tissue, play in the transmission and infection of coronaviruses. Understanding how different compositions of the proteins that make up mucus spread coronaviruses could help identify those who are “super-spreaders” as well as those who could be more vulnerable to becoming infected. That could lead to faster, more accurate data on who will spread the virus or more effective quarantine measures for high-risk populations.

USTAR Professor Carlos Mastrangelo: Electrical and Computer Engineering

Rapid Microfluidic Synthesis of Novel SARS-CoV-2 Entry Inhibitor Antiviral Drugs: This project proposes the construction and testing of a rapid system for the synthesis of novel antiviral drugs to combat the SARS-CoV-2 virus. Unlike conventional drug development cycles which require lengthy combinatorial drug discovery experiments, the new synthesis system can rapidly produce new antivirals in a deterministic manner from existing information of the virus-cell interaction.

Assistant Professor Swomitra Mohanty: Materials Science and Engineering

Chemical free inactivation of Coronavirus via electroactive nanostructured cupric oxide (ENCO): Mitigating viral transmission routes are critical in containing infections such as COVID-19. Standard methods for disinfection use chemicals, however, these have adverse health effects. These approaches focus on surface treatments. Very little is done for airborne transmission other than social distancing and masks. The purpose of this project is to engineer an electroactive nanostructured cupric oxide (ENCO ) material for chemical-free disinfection of viruses. The copper in the nanomaterial is known to inactivate viruses. Seed funding will enable feasibility studies that will lead to large grants focusing on integrating the ENCO material into personal protective equipment, and air purifying systems.

USTAR Professor Massood Tabib-Azar: Electrical and Computer Engineering

Detection of Airborne COVID-19 Using Capsid Protein Aptamers in Exhaled Air: Professor Tabib-Azar has received a $200,000 rapid response grant from the National Science Foundation to develop a coronavirus test that is portable, reusable and produce results in a matter of seconds. He has already created a prototype device to detect the Zika virus. The sensor maintains its speed, specificity and reproducibility while it shortens the time of recognizing and detecting the virus. The sensor is about the size of a quarter and connects to a cellphone via Bluetooth. The sensor uses single-strand DNA, and simply requires the user to talk or blow into it to produce a saliva sample. If the virus is present, those strands would attach to the virus’ proteins. The results would be sent as an alert to an app on the user’s phone in about 60 seconds.

USTAR Professor Tolga Tasdizen: Electrical and Computer Engineering

AI/CXR Early Warning System for Infectious Respiratory Disease Outbreaks: The novel coronavirus pandemic has demonstrated the shortcomings of the healthcare system to cope with a rapidly increasing population-wide infection. Early containment efforts can stop pandemics before they happen or lessen resurgence of disease. This project proposes an early warning system for respiratory infection outbreaks using Artificial Intelligence analysis of routine chest x-rays.