Mike Scarpulla and his engineering team are studying new ways to produce solar panels quickly and make them more efficient, and their work is getting recognized.

On Monday, Oct. 6, Scarpulla, an associate professor at the University of Utah, will speak at the bi-annual Bay Area Photovoltaic Consortium (BAPVC) meeting at the University of California, Berkeley campus about his research of using high-powered lasers to help produce cadmium telluride (CdTe) solar panels. Scarpulla, who is collaborating on the research with Professor Chris Ferekides from the University of South Florida, is one of only five investigators from the consortium invited to speak at the meeting based on the team’s research and its successful collaboration within and outside of the consortium. BAPVC consists of 32 research groups from universities around the country, including Stanford, the California Institute of Technology, Purdue, Massachusetts Institute of Technology, and Berkeley.

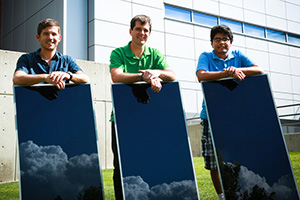

Scarpulla (pictured, center) and his team, which includes postdoctoral fellow Brian Simonds (pictured, left), graduate student Sudhajit Misra (pictured, right) and past undergraduate student Mitchell Hymas (not pictured), are developing ways to use lasers to change the composition or improve the quality of micron-thick layers of CdTe that are deposited directly on sheets of glass to produce thin-film solar panels.

“Probably like most science-minded kids, I’ve been fascinated by lasers since elementary school. The only difference is that we’ve figured out some exciting uses for them, so now I actually get to use them daily,” said Scarpulla, who teaches in both the electrical and computer engineering and materials science and engineering departments at the U. “What we’re looking at is whether you can replace [current] state-of-the-art processes with ones using lasers to do it faster, better or cheaper.”

Like computer chips, most solar panels are made from semiconductor wafers that are produced by melting and then slowly cooling silicon. Many individual solar cells are assembled on a wafer to make a solar panel, which takes energy and time. One of the key advantages of using CdTe is a thin film of this material can be coated on the whole panel at once from a vapor of CdTe.

While silicon solar panels can be slightly more efficient than CdTe panels, the gap has been closing rapidly in the past few years. Also, “CdTe beat silicon to the goal of manufacturing modules at less than $1 per watt generation capacity, and it is still winning in terms of cost-per-watt,” Scarpulla said.

Another advantage to cadmium telluride is that it can perform better under hot weather.

“One place where CdTe can really win is in hot climates like deserts or even Salt Lake City in the summer,” he said. “What happens is the efficiency of cadmium telluride degrades less as a function of temperature.”

So far, Scarpulla’s team has been meeting its goals and said companies could produce commercial panels with this new process in five years if all goes well.

“The manufacturing cost-per-watt is what we’re really after with this research,” he said. “My research group is dedicated to make solar electrical generation cost-effective so it can become widespread. We aim to enable the next breakthroughs to make CdTe technology clearly win out over silicon technologies.”

The Bay Area Photovoltaic Consortium was formed in 2012 with a $25 million grant from the U.S. Dept. of Energy. Solar companies such as GE Global Research and SunPower are also involved in the group.

The number of solar-powered installations is growing in the U.S, according to the Solar Energy Industries Association. More than half a million homes and businesses have a solar installation, and during the first half of this year, 53% of all new electric capacity installed has come from solar, according to the association.

In the past three years, the total costs of installing solar panels on homes as well as in utility-scale installations have been cut in half. “We are living in a pivotal decade of transition for solar energy,” said Scarpulla. “I feel lucky that I’m able to be part of making it happen.”